Bidirectional Buck Boost Converter Topologies

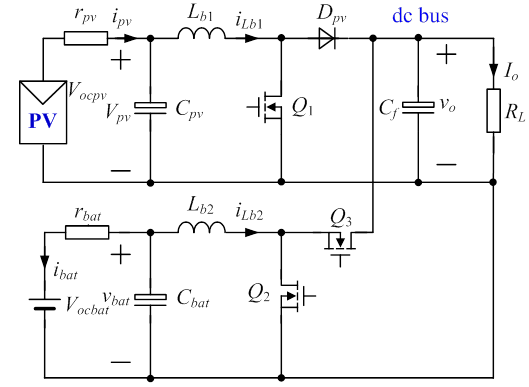

A DC-to-DC converter is an electronic circuit or electromechanical device that converts a. Most DC to DC converter circuits also regulate the output voltage. However, all switching regulator topologies can be made bidirectional and able to. Many laptop and desktop motherboards include interleaved buck regulators,. Bidirectional buck-boost dc-dc converter topology with a full-bridge block including only one inductor and one AC capacitor. The two main switches for the buck-boost stage operate at 20 kHz to produce a fully rectified sinusoidal waveform. The inductor and two buck-boost switches are.

Hi, What have you done so far? And what are the results? It sounds as if you want others to do your research job. Klaus I'm doing a lot of analysis here, trying out different configurations. Calculations are massive. Issues here are that the magnetic core is supposed to be very light, probably less than 5g and this means a very small window area. At the end the inductor is copper loss limited.

I've gone past that point though so I came up with an optimum frequency around 1.5MHz giving me a winding resistance lower than 1ohm. So I now have to tackle switching losses.

I'm practically leaving out the use of diodes to reduce switching losses and to ensure CCM so I'm going to use synchronous switching. I have also looked up some topologies on the internet but the switching frequencies are quite low for this efficiency spec considering switching losses at 1.5MHz. The highest I found was about 1MHz but output power was way higher than 65+-5W indicating a possibility. While I'm doing some more work here, I'd like some help. I said that a long list would be preferred. All I meant was that I need as much contributions as I can get.

Hi, Please what are the practical bidirectional topologies for non-isolated buck-boost converters for efficiencies above 95% at 1.5MHz switching frequency and output power above 65W? A long list would be appreciated. To be clear, a 'topology' is the general converter circuit, which you've apparently already settled on (buck-boost).

Sounds like you're looking for help with specific component selection, though without knowing the I/O voltage ranges it's impossible to start. Also the fact that you're aiming at such a high frequency suggests you're going for something very compact/lightweight at the expense of slightly less efficiency. To be clear, a 'topology' is the general converter circuit, which you've apparently already settled on (buck-boost). Sounds like you're looking for help with specific component selection, though without knowing the I/O voltage ranges it's impossible to start. Also the fact that you're aiming at such a high frequency suggests you're going for something very compact/lightweight at the expense of slightly less efficiency. At first I was stuck in determining an arrangement that would be able to do the bidirectional requirement. I've been able to figure out an arrangement that I'm still trying out.

The I/O voltage ranges from 0 to 5V. When I calculated for the winding resistance of the inductor, I got a value a little below 0.8ohm.

At first I was thinking it might suffice. Now, it doesn't seem like that anymore. It feels like I'll have to perform some magic to get it to that efficiency at that ohmic value [LAUGHS]. But then I'm getting 94.97% efficiency with simulation but this value is measured at saturation which leaves me with doubts.

Makes me think I'd made a mistake while selecting the core. I think I have to go over the selection process again. Season 2 90210. I need some help, seriously. I'm selecting the I/O voltage at operating points with Duty*Gcontroller. Is that correct?

I'll appreciate any help you offer me. I'm still on the power stage design. - - - Updated -.

Without knowing the I/O voltage ranges it's impossible to start. By I/O here, you mean the input and output ranges of the converter? I thought you were asking of the I/O voltage range of the power management system. The converter input is 9.6 to 12.6V; output is 5V for buck operation and 20V for boost. Charging voltage is 20V.

I mentioned 0 to 5V earlier.  That's the I/O range from the management system. The proper voltage level from management system is supposed to be calculated for each mode of operation?

That's the I/O range from the management system. The proper voltage level from management system is supposed to be calculated for each mode of operation?